Automatic Capsule Elevator

Automatic Capsule Elevator Specification

- Type

- Automatic Capsule Elevator

- Voltage

- 220V / 380V

- Inclination

- 90 (vertical)

- Hoist Way Size

- 600mm x 600mm

- Load Capacity

- 5070 kg/batch

- Door Opening Size

- 400mm x 400mm

- Car Dimension

- 450mm x 450mm x 700mm (approx)

- Overhead Height

- 1500mm

- Machine Room Size

- Not required (machine-roomless design)

- Noise Level

- 65 dB

- Usage

- Pharmaceuticals, Capsule Filling Line integration

- Pit Depth

- 150mm

- Material

- Stainless steel (SS304/SS316)

- Drive Type

- Electric motor drive

- Power Supply

- AC, 50Hz/60Hz

- Speed

- 610 meters/minute

- Max. Lifting Height

- 3.5 meters

- Max. Lifting Weight

- 70 kg

- Mechanism Type

- Belt-driven vertical conveyor

- Working Temperature

- 5C 40C

- Control Device

- PLC Control Panel

- Safety Device

- Overload protection, Emergency stop

- Capacity

- Up to 5000 capsules/min

Automatic Capsule Elevator Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 50 Sets Per Month

- Delivery Time

- 1 Week

About Automatic Capsule Elevator

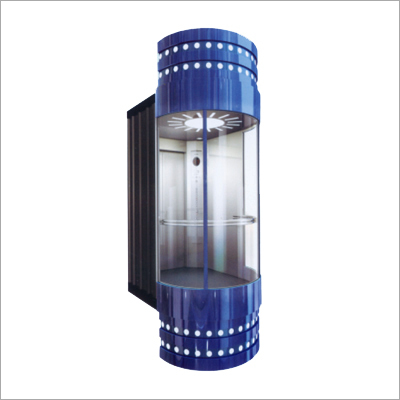

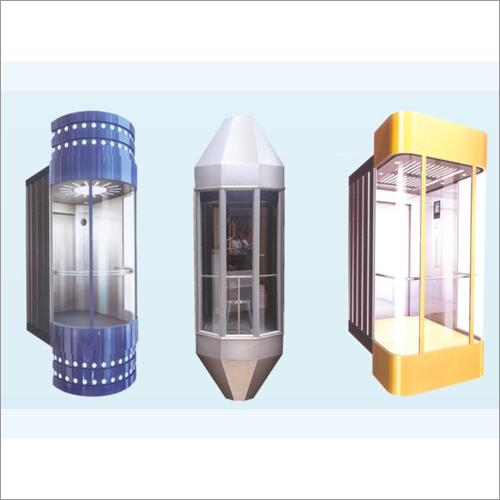

Flawless and reliable, this Automatic Capsule Elevator is a perfect option for installing in indoor areas. The side of this elevator, which is displayed, is made of highly reliable glass. Also the lights, and handle grills are installed within this elevator which gives a luxurious feel to anyone who elevates or descends in it. It functions smoothly and have enough space for a bunch of people to stand comfortably. The elevator consists of highly reliable parts and tools, which assures for its long lasting and never fading quality.

Parameters for Option 1

| Load | Car Inside | Left Well | Entrance | |||||||

| Person | Kgs. | A | B | J | G | C | D | F | H | E |

| 10 | 680 | 1100 | 1300 | 1400 | 650 | 2200 | 1325 | 1330 | 1100 | 800 |

| 13 | 884 | 1200 | 1400 | 1550 | 700 | 2400 | 1425 | 1430 | 1100 | 900 |

| 16 | 1088 | 1300 | 1500 | 1700 | 750 | 2800 | 1530 | 1530 | 1200 | 1000 |

Parameters for Option 2

| Load | Car Inside | Left Well | Entrance | |||||||

| Person | Kgs. | A | B | G |

| C | D | F | H | E |

| 10 | 680 | 1250 | 1300 | 250 |

| 2200 | 1450 | 1480 | 580 | 800 |

| 13 | 884 | 1400 | 1400 | 300 |

| 2400 | 1550 | 1630 | 650 | 900 |

| 16 | 1088 | 1550 | 1500 | 350 |

| 2800 | 1780 | 1650 | 790 | 1000 |

Efficient, Seamless Capsule Transport

Designed to support continuous and automatic movement of empty or hard gelatin capsules, this elevator enhances productivity for pharmaceuticals and capsule filling lines. Its touch screen PLC control panel simplifies operation, enabling precise oversight and exceptional consistency in capsule handling. The vertical belt-driven system guarantees smooth transport, reducing manual effort and minimizing potential for product loss or contamination.

Advanced Safety and Hygiene Features

Safety protocols include built-in overload protection and an emergency stop function to ensure secure operation. The elevator boasts an IP54 protection grade, shielding internal components from dust and water splash. Maintenance is simplified by a design that supports easy disassembly, enabling operators to conduct regular cleaning and inspection, thus meeting high hygiene standards required in pharmaceutical environments.

FAQs of Automatic Capsule Elevator:

Q: How does the touch screen control system simplify capsule elevator operation?

A: The touch screen PLC interface provides an intuitive, user-friendly platform for monitoring and managing elevator functions. This streamlines operations by allowing quick adjustments, real-time oversight, and seamless integration with capsule filling lines, thereby improving accuracy and efficiency.Q: What is the process for feeding and discharging capsules with this elevator?

A: Capsules are loaded into the hopper, which includes a level sensor to regulate feed rates. The machine then transports capsules vertically using a belt-driven system, and the automatic chute outlet ensures continuous discharge at the destination, reducing blockages and manual handling.Q: When is cleaning required for the capsule elevator, and how is it performed?

A: Regular cleaning is recommended to maintain pharmaceutical hygiene standards. The elevators easy disassembly mechanism allows operators to quickly access internal parts, making thorough cleaning straightforward and time-efficient.Q: Where can this automatic capsule elevator be installed within a facility?

A: The floor-mounted design, vertical inclination, and compact machine-roomless configuration enable installation in a variety of production settings, especially in capsule filling lines within pharmaceutical plants. Its minimal space requirements suit both new and existing layouts.Q: What are the main benefits of using this elevator in a pharmaceutical capsule filling line?

A: Key advantages include high transport capacity, reliable continuous operation, reduced manual labor, enhanced safety, low noise ( 65 dB), and assured hygiene. These features collectively help optimize workflow and maintain product integrity.Q: How does the overload protection and emergency stop mechanism improve safety?

A: These built-in safety devices monitor load conditions and can immediately halt the elevator in case of a malfunction or overload, protecting both operators and equipment from potential accidents or damage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Capsule Elevators Category

SS Glass Capsule Cabin

Price Range 90000.00 - 200000.00 INR / Set

Minimum Order Quantity : 1 Set

Mechanism Type : Other, Electric Traction

Max. Lifting Weight : 1000 kg

Drive Type : Other, Traction / Elevator System

Max. Lifting Height : Up to 60 m

Hydraulic Capsule Elevator

Price Range 90000.00 - 200000.00 INR / Set

Minimum Order Quantity : 1 Set

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese